| Direct drive horizontal axis wind turbine |

The rotating speed of the wind turbine is low, the rotating speed of the small wind turbine is up to several hundred revolutions per minute, and the rotating speed of the large and medium wind turbine is about tens of revolutions per minute or even ten turns. It is introduced in the “Nacelle appliance and Towers” section. Speed to drive the generator by gearbox. But,it will reduce the efficiency of wind turbine power to use speed-increasing gearbox. Gearbox is quick-wear equipment especially the high speed gearbox. Maintaining gearbox is difficult in nacelle of wind turbine and changing gearbox regularly is very expensive. A low-speed generator designed and manufactured specifically for wind turbines can be driven directly by a wind turbine, which is a multi-pole generator and is often excited by permanent magnets. This section introduces the placement of the nacelle equipment through a direct-drive wind turbine model, which is only a schematic diagram of the main equipment installation placement. |

|

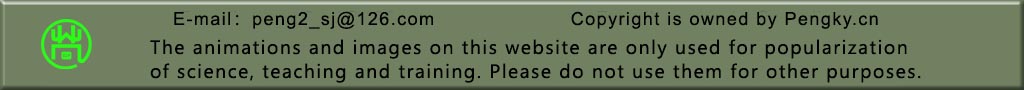

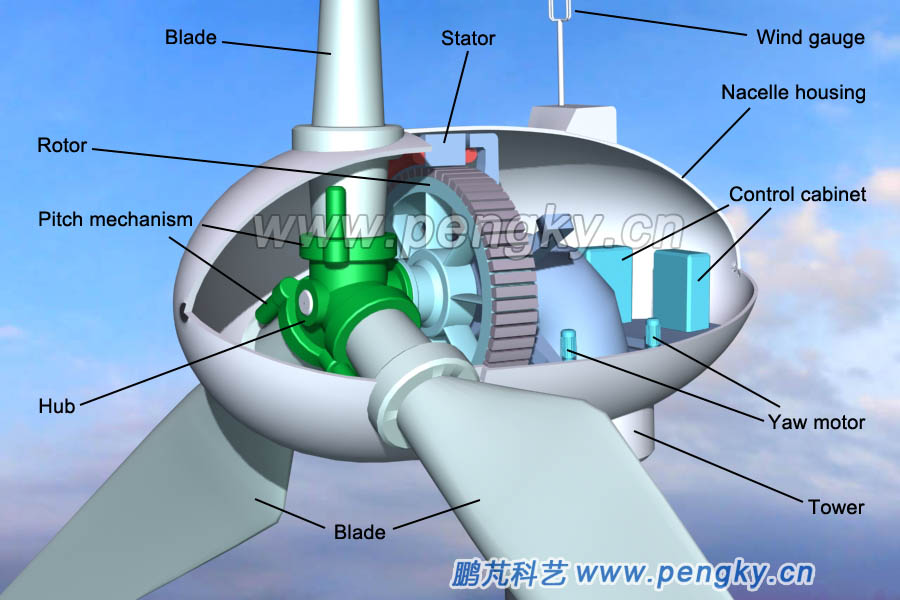

| Figure 1 - There are yaw, stator and rotor spindles in the nacelle |

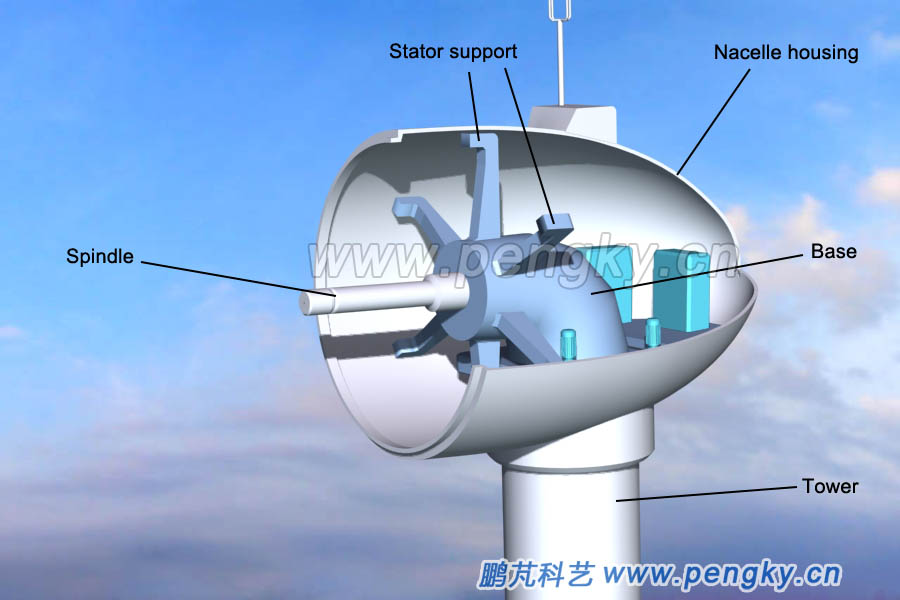

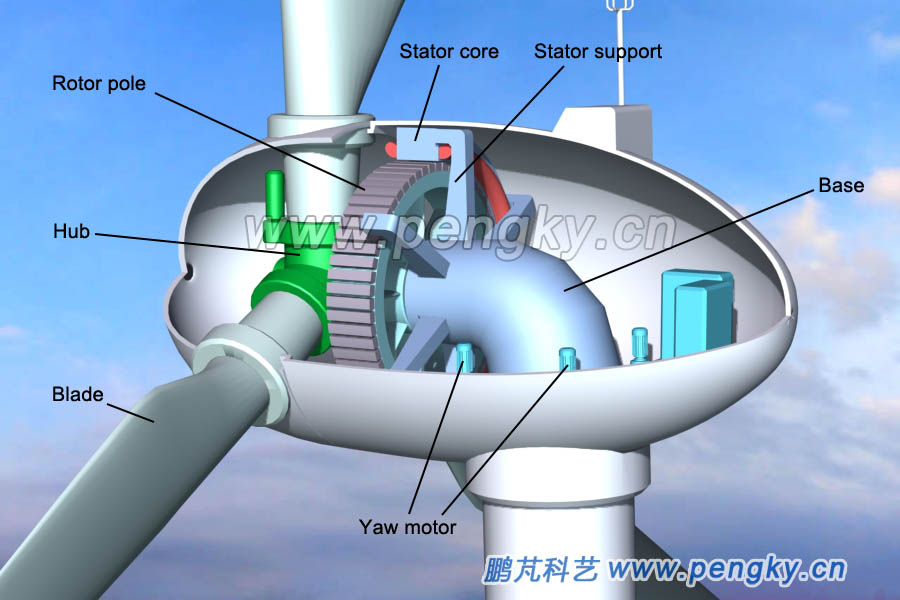

| Install the stator around the coil on the frame of the base, and cut off the stator for the display of the rotor structure, see figure 2. |

|

| Figure 2 - Mounting the stator core and three-phase winding on the frame of the base |

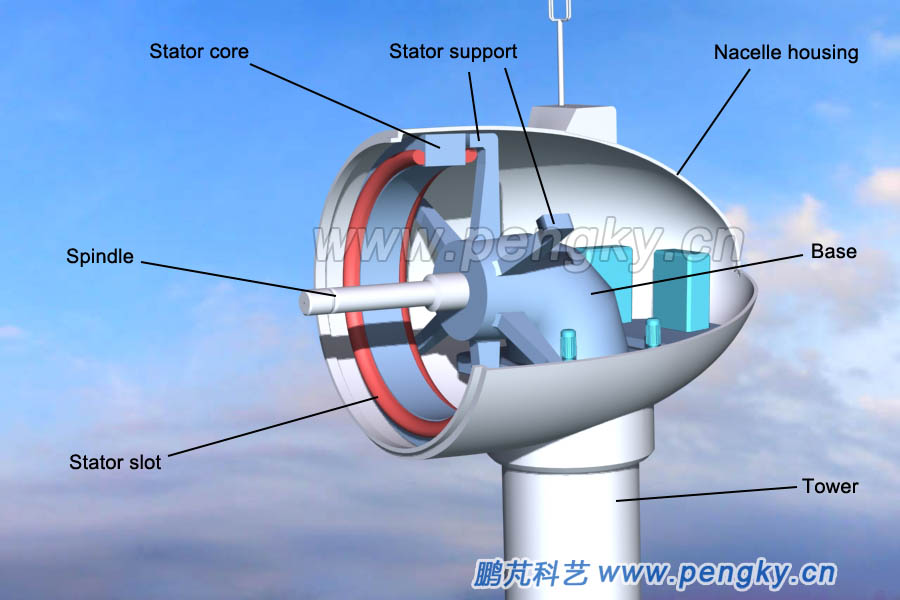

| Mount the inner rotor with the permanent magnetic pole on the shaft of the base, see figure 3. |

|

| Figure 3 - Nacelle with stator and permanent magnet rotor |

| The bladed hub is also mounted on the rotating shaft of the base, and is fixedly connected with the rotor, the wind rotor rotates synchronously rotation, and then the hub cover is installed, as shown in figure 4 |

|

| Figure 4 - One of the basic structure diagrams of a direct-drive permanent magnet wind turbine |

| This is the basic structure of a direct drive permanent magnet wind power generator, and figure 5 is a view of another angle of the wind power generator. |

|

| Figure 5 - Basic structure diagram of direct drive permanent magnet wind turbine |

In the current wind turbines, direct-drive wind turbines are used more and more, and are used in small and medium-sized wind turbines (including vertical-axis wind turbines). Currently, the world's largest horizontal-axis wind turbine is straight driven. It is said to have reached 9MW. Let's watch the 3D animation of a direct-drive permanent magnet wind turbine. |

| Direct-drive permanent magnet wind turbine animation |

In order to improve the efficiency of wind turbines, direct-drive wind turbines are used in variable speed mode, and the speed is adjusted by pitch to obtain the maximum wind energy utilization coefficient. However, the changing speed of the generator causes the frequency of the alternating current to change continuously. In order to input the generated electric energy into the grid, it is necessary to output a stable 50 Hz alternating current, which requires the AC-DC-AC converter to convert the output of the generator to stable 50Hz AC. Since the converter must convert all the power output from the generator, the capacity of the converter must be greater than the power of the generator, called a full power converter. The price of full-power converters is very expensive, which is one of the shortcomings of direct-drive wind turbines. Fortunately, the price of high-voltage and high-power devices is gradually decreasing, which is conducive to the promotion and application of direct-drive wind turbines. Several commonly used direct drive wind turbines are described in the "Direct Drive Wind Turbines" section. |

| Back to Previous Page |